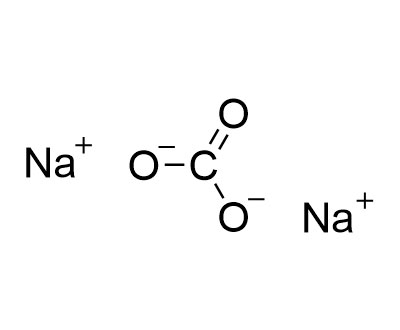

sodium carbonate,Commonly known as soda ash, soda ash, detergent alkali, and also commonly referred to as "alkali" in daily life. Chemical formula: Na2CO3, usually white powder, is a strong electrolyte. The density is 2.532g/cm3, the melting point is 850 ℃, it is easily soluble in water, and has salt like properties.

| Chinese name | 碳酸钠 | English name | sodium carbonate |

|---|---|---|---|

| Chinese alias | 纯碱; | English alias | Calcined soda;Sodium carbonate,(trace metal basis);Carbonic acid disodium salt,Soda ash;Sodium carbonate; |

| CAS | 497-19-8 | Molecular formula | CNa2O3 |

| Molecular weight | 105.98800 | Accurate mass | 105.96400 |

| PSA | 63.19000 | LOGP | -2.44700 |

| UNII | 45P3261C7T |

|---|

Appearance and characteristics:

White odorless powder

Density:

two point five three

Boiling point:

1600°C

Melting point:

851 °C(lit.)

Flash point:

169.8ºC

Refractive index:

one point five three five

Water solubility:

22 g/100 mL (20 ºC)

Stability:

Stable. Incompatible with powdered alkaline earth metals, aluminium, organic nitro compounds, fluorine, alkali metals, nonmetallic oxides, concentrated sulfuric acid, oxides of phosphorus.

Storage conditions:

Low temperature, ventilated, and dry warehouse

RTECS:

XN6476000

Safety instructions:

S36/37-S26-S22-S36-S39

WGK Germany:

two

Hazard category code:

R36

Customs code:

two billion eight hundred and thirty-six million and two hundred thousand

Dangerous goods transportation code:

UN 3082 9/PG 3

Dangerous goods signs:

Xi

Danger signs:

GHS07

Signal words:

Warning

Hazard prevention instructions:

P305 + P351 + P338

Hazard description:

H319

1. Ammonia alkali method: Dissolve the original salt (table salt) in water, add an appropriate amount of lime milk to remove magnesium, and introduce CO2 to remove calcium. Purified saline solution is introduced with ammonia gas for ammonia absorption, and CO2 is then introduced into the ammonia absorption mother liquor for carbonization, resulting in the precipitation of sodium bicarbonate. After filtration and calcination, sodium carbonate is obtained. Add lime milk to the mother liquor and steam out ammonia gas for ammonia absorption.

2. The combined alkali method involves passing ammonia gas through the mother liquor of salt precipitation crystallization for ammonia absorption. The ammonia absorption mother liquor is then passed through CO2 for carbonization, resulting in the precipitation of sodium bicarbonate crystals. After filtration and calcination, pure alkali is obtained. The mother liquor is then subjected to ammonia absorption to precipitate ammonium chloride crystals. After filtration, salt is added to further precipitate ammonium chloride crystals. After filtration, the mother liquor is reused to absorb ammonia, and the cycle continues. The reaction equation is the same as the ammonia alkali method. There are ammonia alkali method, combined alkali method, natural alkali processing, etc. The main reaction of the ammonia alkali method is as follows: the process flow is briefly described as follows: the original salt is dissolved in water, and after removing calcium and magnesium, it is made into refined salt water (also known as secondary salt water, the same below). Secondary saline water is treated with ammonia to produce ammonium salt water with a NaCl concentration of 89 or higher and a ratio of FNH3 to Na+concentration of 1.13-1.18. The oxygen salt water is cooled to 35-38 ℃ and sent to the carbonization section, where it reacts with compressed carbon dioxide from the lime kiln and calcination furnace to generate a sodium bicarbonate suspension. It flows to the filtration section, where sodium oxycarbonate (heavy alkali) crystals are separated from the suspension and sent to the calcination upper section for calcination and decomposition at around 160 ℃ to produce pure alkali products. Filter the mother liquor and mix it with lime milk from the lime section to make a mixed solution, and use steam heating in the distillation tower to steam out the ammonia, which is then used for brine ammonia absorption and recycling. The production process of the combined alkali production method is divided into the alkali production process (also known as the I process) and the ammonium production process (also known as the II process), which co produce pure alkali and ammonium chloride. The mother liquor forms a closed cycle in both processes. The main reaction is the same as the ammonia alkali method. The process flow is described as follows: the original salt (sodium chloride) is washed with saturated salt water to remove calcium and magnesium impurities, and then crushed, washed, thickened, and separated to obtain washing salt with the specified purity (containing NaCl ≥ 98%) and particle size (10-20 mesh), which is sent to the salt precipitation crystallizer. The mother liquor II overflowed from the salt precipitation crystallizer absorbs ammonia in the ammonia absorber to produce ammonia mother liquor II. After clarification, it is sent to the carbonization tower to absorb carbon dioxide (carbonization) and produce a sodium bicarbonate suspension. The sodium bicarbonate suspension is filtered to obtain solid sodium bicarbonate, which is then calcined to obtain pure alkali product. After filtering heavy alkali, the mother liquor (mother liquor I) is converted into ammonia mother liquor I by ammonia absorption. It is then heat exchanged with mother liquor II through a heat exchanger, cooled, and sent to a cold precipitation crystallizer. It is then directly heat exchanged with a cold carrier (brine) or a refrigerant (liquid ammonia) through an external cooler, and partially ammonium chloride is cooled and precipitated at 5-10 ℃. The overflow liquid (semi mother liquor II) from the cold precipitation crystallizer flows into the salt precipitation crystallizer, where washing salt is added to precipitate some ammonium chloride. The ammonium chloride suspension extracted from the cold precipitation and salt precipitation crystallizers is thickened and separated to obtain wet ammonium chloride, which is then sent to a dry ammonium furnace for drying to obtain the ammonium chloride product. The overflow liquid from the salt precipitation crystallizer (mother liquor II) is heat exchanged with the ammonia mother liquor L and then absorbed by ammonia to produce ammonia mother liquor II, which is then sent to the carbonation tower for alkali production. In this continuous cycle, two products, soda ash and ammonium chloride, are continuously produced.

3. Natural alkali processing method - Half alkali process. This method is used to produce soda ash from half alkali as raw material. Some natural alkali processing plants in the United States adopt it. The ore is crushed to about 20 mesh (0.8mm) and sent to the dissolution tank. It is dissolved in circulating mother liquor to make a saturated solution, which enters the clarification tank for clarification. The bottom flow is sent to the thickener, where water is added to wash and recover the alkali in the mud. The overflow liquid from the clarification tank is filtered and sent to the third effect evaporator for evaporation. The crystal slurry taken out from the third effect evaporator is pumped to the thickener and then centrifuged for dehydration to obtain sodium bicarbonate filter cake. After calcination, pure alkali is produced. The one water carbon process method is also a method of producing soda ash from half alkali as raw material, and its product quality is superior to the half alkali process. Most natural alkali processing plants in the United States adopt this method. Grind the ore to

About 6mm, it is sent to the calcination furnace and calcined at around 150 ℃. Most of the ore is crude soda ash, which enters the dissolution tank and is dissolved at slightly lower than 100 ℃. After clarification, it is sent to the three effect evaporator. The concentrated suspended alkali solution is separated to obtain sodium carbonate monohydrate, which is then dried in a dryer to obtain heavy soda ash. Carbonation method is a production method using natural alkali brine as raw material, which is adopted in natural alkali processing in places such as Dabusu in China. The alkali brine extracted from natural alkali or dissolved in water is clarified, preheated, and then carbonated with carbon dioxide. After filtration and calcination, pure alkali products are obtained. In the mid-1980s, the ammonification carbonization method was successfully developed, which involved first absorbing nitrogen and then carbonizing the refined alkali brine, and the subsequent process remained the same. Compared with direct carbonization, the sodium utilization rate of ammonification carbonization method can be increased from 25% to 65% to 70%. The natural alkali brine evaporation method uses dissolved natural alkali ore or natural alkali excavated from alkali lakes to produce alkali brine, which is then refined, separated, preheated, evaporated, separated, and calcined to produce pure alkali. The sodium carbonate synthesis method involves dissolving crude sodium carbonate and sodium bicarbonate in steam, settling to remove impurities, and then clearing the liquid. After reacting with carbon dioxide to a certain concentration, it is distilled, cooled, and crystallized to obtain sodium sesquicarbonate. The reaction equation is as follows: The natural alkali method uses natural alkali as the raw material and dissolves it in steam to clarify and remove impurities. The clear liquid contains components such as sodium carbonate, sodium bicarbonate, and sodium sulfate, and is carbonized by kiln gas to partially carbonize Na2CO3 into NaHCO3. The corresponding complex is evaporated and precipitated at 60 ℃, and the finished product of sodium sesquicarbonate is separated and prepared. The mother liquor can be evaporated again to precipitate saltpeter. Its reaction journey formula: Currently, China uses the ammonia alkali method or the combined alkali method to directly produce edible soda ash. In the production of light soda ash, refining processes for arsenic and heavy metal impurities should be added. For other processes, please refer to industrial sodium carbonate.

4. Using industrial anhydrous sodium carbonate as raw material, stir and add 0.4% sodium hydroxide solution to a density of 1.28-1.30, keep warm for 10 hours, fully precipitate iron hydroxide, magnesium hydroxide, and calcium hydroxide, filter out the precipitate, slowly introduce washed carbon dioxide into the filtrate to neutralize excess sodium hydroxide, generate sodium bicarbonate, evaporate and crystallize to obtain crystalline sodium carbonate, and calcine and dehydrate at 560-580 ℃ to obtain anhydrous sodium carbonate reagent. If the intermediate product sodium carbonate obtained is dissolved, filtered, and recrystallized once, it can be calcined to obtain analytical grade or superior grade reagents. 5. First, place deionized water into a stainless steel bucket and slowly add industrial grade anhydrous sodium carbonate (2.5 parts carbon sodium) while stirring. Then, heat to 60 ℃ and filter until completely dissolved. The colorless and transparent filtrate was left to cool and crystallize (stirring frequently to obtain small particles for easy drying), resulting in the crystallization of sodium carbonate. After centrifugal dehydration and inspection of the ion content of the yak (if it is too high, wash it with cold deionized water), it is loaded into a stainless steel tank, heated and melted until small particles of monohydrate and dihydrate precipitate (white powder), and then taken out and shaken dry. After drying, the mixture of sodium carbonate and sodium carbonate is loaded into a dryer and dried at around 110 ℃ to obtain anhydrous sodium carbonate.

Basic chemical raw materials are widely used in industries such as pharmaceuticals, papermaking, metallurgy, glass, textiles, dyes, and as fermentation agents in the food industry.