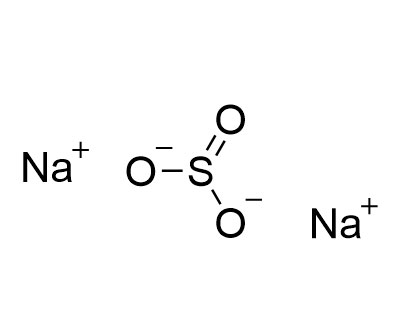

Sodium sulfite (chemical formula: Na2SO3) is an inorganic compound. It is a white granular powder at room temperature, soluble in water, and has reducibility. When heated, it dismutates into sodium sulfide and sodium sulfate, and gradually oxidizes to sodium sulfate when placed in air. It can exist in three forms: anhydrous, heptahydrate, and decahydrate, with anhydrous being the least susceptible to oxidation. Its aqueous solution becomes alkaline due to hydrolysis and releases toxic sulfur dioxide gas during acidification. Sodium sulfite can be prepared by adding sulfur dioxide into a sodium hydroxide solution. When sulfur dioxide is excessive, sodium bisulfite is generated. Sodium sulfite can be used as a developer, preservative for dried fruits and meat, deoxidizer in the printing and dyeing industry, and as a reducing chemical reagent, applied in chemical and laboratory production and synthesis.

| Chinese name | 亚硫酸钠 | English name | Sodium sulfite |

|---|---|---|---|

| Chinese alias | 无水亚硫酸钠;硫养粉;亚硫酸钠(无水);硫氧粉; | English alias | anhydrous sodium sulphite;Natrii sulphis;Sodium sulphite;Sodium sulfite anhydrous;disodium,sulfite; 查看更多英文别名 |

| CAS | 7757-83-7 | Molecular formula | Na2O3S |

| Molecular weight | 126.04300 | Accurate mass | 125.93600 |

| PSA | 82.40000 | LOGP | -0.13840 |

| UNII | VTK01UQK3G |

|---|

Appearance and characteristics:

White crystal or powder

Density:

two point six three

Melting point:

500 °C

Refractive index:

one point four eight four

Water solubility:

23 g/100 mL (20 ºC)

Stability:

Stable. Incompatible with strong acids. Moisture and air sensitive.

Storage conditions:

Low temperature, ventilated, and dry warehouse

RTECS:

WE2150000

Safety instructions:

S24/25

WGK Germany:

one

Hazard category code:

R22; R36/37/38

Customs code:

two billion eight hundred and thirty-two million and one hundred thousand

Dangerous goods signs:

Xn

Supplementary Hazard Statement:

Contact with acid will release toxic gases.

(1) The pure alkali liquid absorption method introduces the sulfur dioxide containing gas obtained from the combustion of sulfur from the bottom of the absorption tower, and absorbs it in reverse flow with the pure alkali solution to generate sodium bisulfite solution, which is sent to the neutralization tank and slowly added to the pure alkali solution for neutralization reaction until slightly acidic. Then add caustic soda solution to achieve a pH value of 11-12. After decolorization, filtration, clarification, evaporation crystallization, centrifugal dehydration, and drying at 250-300 ℃, anhydrous sodium sulfite product is obtained. The reaction equation is as follows:

(2) The gas containing S0z produced by sulfur combustion is introduced into the absorption tower and absorbed in reverse flow with a pure alkali solution with a relative density of 1.21 (25 ° B è). The resulting sodium bisulfite solution has a pH value of 5-6 and is neutralized to a slightly acidic state in a neutralization tank with a pure alkali solution with a relative density of 1.21, and then heated to above 102 ° C; Add caustic soda solution with a relative density of 1.19 to neutralize to a pH value of 11-12, remove iron, and obtain sodium sulfite solution; The neutralizing solution is evaporated and concentrated under vacuum (26.7kPa), and then separated by crystallization. The product is obtained by drying with air flow at 250-300 ℃ to remove the crystallization water. The reaction equation is as follows:

(3) When sodium sulfite heptahydrate is heated to around 50 ℃, the crystals dissolve in the crystallization water and anhydrous crystals precipitate. Filter the crystals of anhydrous material while hot and dry them at 100-110 ℃. The filtration and drying process should avoid contact with air and can be carried out under the protection of nitrogen or hydrogen gas.

4. Adopt absorption method. Absorb sulfur dioxide with food grade soda ash solution, saturate it, and then add refined sodium hydroxide solution to obtain crystalline sodium sulfite through crystallization. After heating and dehydration, obtain edible anhydrous sodium sulfite.

5. Under heating and stirring, dissolve 50kg of industrial sodium sulfite in 200kg of distilled water. After complete dissolution, filter out insoluble impurities. Add a small amount of sodium hydroxide solution to precipitate metals such as magnesium and calcium. After filtration, heat and evaporate to continuously precipitate small sodium sulfite crystals. Remove and drain in a timely manner, centrifuge and spin dry (moist and prone to oxidation). Dry the dried crystals at around 200 ℃.

Used as a stabilizer for artificial fibers, fabric bleaching agent, photographic developer, dye bleaching deoxidizer, fragrance and dye reducing agent, papermaking lignin remover, etc.