Physical and Chemical Properties and Hazardous Characteristics of Acetic Acid

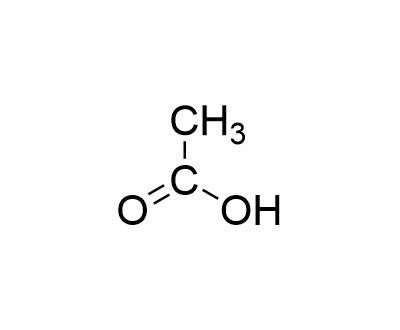

Chemical name Chinese name: 乙酸 、醋酸 English name: Acetic acid Hazardous code: 81601 CAS number: 64-19-7 Molecular formula: C2H4O2 Molecular weight: 60.05 Hazard category: Class 8.1 Acidic corrosive material UN number: 2789 |

Hazard Overview Health hazards: Inhaling the vapor of this product can cause irritation to the nose, throat, and respiratory tract. Has a strong irritant effect on the eyes. Skin contact can cause redness in mild cases and chemical burns in severe cases. Accidentally taking concentrated acetic acid can cause erosion in the oral and digestive tracts, and in severe cases, it can lead to death due to shock. Chronic effects: eyelid edema, conjunctival congestion, chronic pharyngitis, and bronchitis. Long term repeated exposure can cause dryness, defatting, and dermatitis of the skin. Environmental hazards: Harmful to the environment and can cause pollution to water bodies. Explosive hazard: This product is flammable, corrosive, and highly irritating, and can cause burns to the human body. |

Emergency measures Skin contact: Immediately remove contaminated clothing and rinse with plenty of flowing water for at least 15 minutes. Seek medical attention. Eye contact: Immediately lift the eyelids and thoroughly rinse with plenty of flowing water or saline solution for at least 15 minutes. Seek medical attention. Inhalation: Quickly leave the scene and move to a place with fresh air. Keep the respiratory tract unobstructed. If breathing is difficult, administer oxygen. If breathing stops, immediately perform artificial respiration. Seek medical attention. Ingestion: Rinse mouth with water and seek medical attention. |

Fire protection measures Hazardous characteristics: Flammable, its vapor can form explosive mixtures with air, and can cause combustion and explosion when exposed to open flames or high heat energy. Contact with chromic acid, sodium peroxide, nitric acid or other oxidants poses a risk of explosion. Corrosive. Harmful combustion products: carbon monoxide, carbon dioxide Fire extinguishing method: Spray the escaping liquid with water to dilute it into a non flammable mixture, and protect firefighters with misty water. Extinguishing agent: spray water, insoluble foam, dry powder, carbon dioxide. |

Emergency response to leakage Quickly evacuate personnel from the contaminated area to a safe zone, isolate them, and strictly restrict their entry and exit. Cut off the fire source. It is recommended that emergency personnel wear self-contained positive pressure respirators and acid and alkali resistant work clothes. Do not come into direct contact with the leaked material. Cut off the leakage source as much as possible. Prevent the flow into restricted spaces such as sewers and drainage ditches. Minor leakage: Mix sand, dry lime, or soda ash. Massive leakage: Construct embankments or dig pits to contain it. Spray like water cools and dilutes steam, protects on-site personnel, and dilutes leakage into incombustible materials. Transfer to a tanker or dedicated collector using an explosion-proof pump, and recycle or transport to a waste disposal site for disposal. |

Handling and Storage Precautions for operation: Closed operation, strengthen ventilation. Operators must undergo specialized training and strictly adhere to operating procedures. It is recommended that operators wear self-priming filter type gas masks (half masks), chemical safety goggles, acid and alkali resistant plastic work clothes, and rubber acid and alkali resistant gloves. Keep away from sources of fire and heat, and smoking is strictly prohibited in the workplace. Use explosion-proof ventilation systems and equipment. Prevent steam leakage into the workplace air. Avoid contact with oxidants and alkalis. Handle with care during transportation to prevent damage to packaging and containers. Equip with corresponding types and quantities of fire-fighting equipment and emergency response equipment for leaks. Empty containers may contain residual harmful substances. Storage precautions: Store in a cool and ventilated warehouse. Stay away from sources of fire and heat. During the freezing season, the storage temperature should be kept above 16 ℃ to prevent solidification. Keep the container sealed. It should be stored separately from oxidants and alkalis, and avoid mixing storage. Adopt explosion-proof lighting and ventilation facilities. Prohibit the use of mechanical equipment and tools that are prone to generating sparks. The storage area should be equipped with emergency response equipment for leaks and suitable containment materials. |

Contact control and individual protection Exposure limit: China MAC (mg/m3) 20; Former Soviet Union MAC (mg/m3) 5 Engineering control: The production process is sealed and ventilation is strengthened. Provide safety shower and eye wash equipment. Respiratory protection: When the concentration in the air exceeds the standard, a self-priming filter type gas mask (half face mask) should be worn. Wear an air respirator during emergency rescue or evacuation. Eye protection: Wear chemical safety goggles. Body protection: Wear acid and alkali resistant plastic work clothes. Hand protection: Wear rubber acid and alkali resistant gloves. Other protections: Smoking is strictly prohibited at the work site. After work, take a shower and change clothes. Pay attention to personal hygiene and cleanliness. |

Physical and chemical properties Content level one ≥ 99.0%; Level 2 ≥ 98.0% Appearance and Characteristics: Colorless and transparent liquid, with a pungent and sour odor. Solubility: soluble in water, ether, and glycerol, insoluble in carbon disulfide. Melting point (℃): 16.7 Boiling point (℃): 118.1 Flash point (℃): 39 Saturated vapor pressure (kPa): 1.52 (20 ℃) Relative density (water=1): 1.05 Relative vapor density (air=1): 2.07 Explosion limit% (V/V): 4.0-17.0 Critical temperature (℃): 321.6 Critical pressure (MPa): 5.78 Ignition temperature (℃): 463 Main applications: Used for manufacturing acetate salts, cellulose acetate, pharmaceuticals, pigments, esters, plastics, fragrances, etc. Prohibited substances: alkalis, strong oxidants. |

Toxicological data LD50: 3530 mg/kg (oral administration in rats); 1060 mg/kg (rabbit transdermal) LC50: 13791mg/m3, 1 hour (inhaled by mice) |

Transportation information Packaging method: Small opening aluminum drum; Ordinary wooden box or semi checkered wooden box outside glass bottles or plastic drums (cans); Ordinary wooden box outside frosted or threaded glass bottles; Screw mouth glass bottles, iron cap pressed mouth glass bottles, plastic bottles, or ordinary wooden boxes outside metal drums (cans); Threaded glass bottles, plastic bottles, or tin plated steel drums (cans) are filled with bottom plate flower boxes, fiberboard boxes, or plywood boxes. Transportation precautions: This product is transported by railway using aluminum tank trucks provided by the enterprise. Approval from relevant departments is required before shipment. When transporting non canned goods by railway, the dangerous goods loading table in the "Dangerous Goods Transport Rules" of the Ministry of Railways should be strictly followed for loading. When shipping, the packaging should be intact and the loading should be secure. During transportation, it is necessary to ensure that the container does not leak, collapse, fall, or be damaged. The tank truck used for transportation should have a grounding chain, and a perforated partition can be installed inside the tank to reduce static electricity generated by vibration. It is strictly prohibited to mix and transport with oxidants, alkalis, edible chemicals, etc. When transporting by road, follow the prescribed route and do not stay in residential or densely populated areas. |